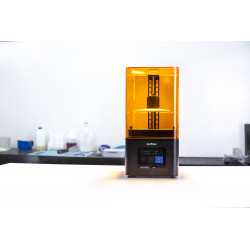

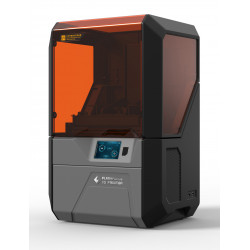

Zortrax Inkspire – High Definition DLP 3D printer with Wifi & Ethernet

Buy the wonderful high-resolution Zortrax Inkspire DLP 3D printer and produce at high speed. Simply connect your computer, notebook or mobile device to this additive manufacturing system via Ethernet or Wifi. Start creating fine details and stunning surfaces. The Inkspire works with DLP resins from different suppliers. Furthermore, you can use your favorite slicer to manufacture .cw files. Connect multiple Zortrax Inkspire devices together to create a flexibly scalable generative production facility. This device is ideal for the making of precision mechanics, prototypes, small series as well as medical and dental technology.

Product features of the Zortrax Inkspire:

- This DLP 3D printer offers you up to 8x faster 3D printing than SLA

- Realize up to 9x higher accuracy than SLA

- The production speed is 20-36 mm/h

- The XY resolution is 50x50 microns

- The minimum layer thickness is 25 microns

- Suitable for additive series manufacturing

- Produce with resins (photopolymers: 405 nm polymerization) from third-party suppliers

- Use your favorite slicing software (from external vendors)

- The file formats .zcodex and .cw are supported

- The installation space measures 74x132x175 mm

- Wifi and Ethernet connection available

- Features an intuitive touch-screen user interface

3D printing enhanced with resin

The Zortrax Inkspire uses DLP technology. It uses a high-resolution LCD display with UV LED backlighting to cure liquid photopolymer resin layer by layer. 3D printing with resin enables higher resolution, more beautiful surface quality and improved material properties.

Microscopic precision

3D print smallest objects with the Zortrax Inkspire. The minimum printable size is a cuboid of 50x50x25 microns. This DLP 3D printer always works with high resolution, precession and reliability.

Constant production speed

During production, the same high manufacturing speed of 20-36 mm/h is maintained, regardless of how much work area is filled in the installation space. Produce a large variety of components quickly and efficiently using additives. It is best to place several components side by side in the installation space.

Use third-party resin

With the Zortrax Inkspire you can process all UV DLP resins available on the market. Use all photopolymers that can be cured with UV light with a wavelength of 405 nm. They are all supported. So you can use our PrimaValue DLP resin or Wanhao, Monocure and other resins with this 3D printer. This allows you to choose from a wide range of bright colors and convincing material properties for your components.

Simple and fast settings

The 3D print settings can be changed quickly and easily. For example, change the exposure time for each layer or the distance between layers. Experience 3D printing as you want it.

Explore UV-LCD technology

Stereolithography (SLA) has been on the market for a long time. Digital Light Processing (DLP) technology works as a 3D printing technology with the photopolymerization of plastics. When using SLA technology, manufacturing precision is constant, but the working speed is inversely proportional to the size of the working area the model occupies. DLP technology operates at a constant production speed, but accuracy often decreases with increasing use of the work area. Not so with the Zortrax UV-LCD DLP 3D printer. Its optimized exposure and 3D printing unit gives you consistently high production speed and precision no matter how much workspace you use.

Additive manufacturing – serial production

The Zortrax Inkspire ensures consistently high working speed and accuracy regardless of how much of the working area is used. If your 3D printer produces 50 to 80 parts in 1 hour 30 minutes, 30 3D printers working together can offer an approximate monthly output of 360,000 to 500,000 parts. That's why you can use your Zortrax Inkspire as a production machine in easily and flexibly scalable farms of 3D printers. This enables you to produce small batches quickly and cost-effectively.

Compatible resins

Your Zortrax Inkspire works with a specially optimized Zortrax Resin Basic. Do you want to work with your favorite DLP resin? That's no problem; you can simply use external DLP resin. All resins with a polymerization wavelength of 405 nm are fully supported. This means that the UV light in this wavelength range cures the resin.

Zortrax Resin Basic

Zortrax Resin Basic is a photopolymer specially developed and optimized for the Zortrax Inkspire. This material guarantees excellent attention to detail with top mechanical properties at the same time. It is available in white.

External resins

External resins compatible with your Zortrax Inkspire contain photopolymers specially optimized for DLP-3D printers. They are designed for use in dental prosthetics, jewelry design and other applications.

Applications

3D printing with resin is a technology perfect for professionals and specialists. Create very small yet incredibly detailed models with impressive material properties. The precision and speed of the Zortrax Inkspire make it an ideal tool for dentists, jewelers, engineers and designers.

Flexible production

The Zortrax Inkspire 3D Printer provides flexible, scalable manufacturing capabilities for companies and professionals who want to generatively produce small and precise parts themselves. It is also a perfect tool for engineers working in research and development departments and on production lines. This DLP manufacturing machine is suitable for applications in the automotive, aerospace and consumer electronics industries.

Art and Entertainment

Small and stylish models made from resin on this DLP-3D printer give you enormous possibilities as an artist and in the entertainment industry. For example, you can make detailed pieces for chessboards. Small, very complex and limited edition gifts are perfect for marketing and PR departments.

Dental prosthetics

Resin 3D printers are especially useful for making complex dental models faster, more efficient, and less expensive. Compared to traditional dental modeling techniques, your Zortrax Inkspire enables less invasive procedures that require little or no patient involvement. You can use 3D printed models of your patients' oral cavities for additive fabrication of dental models, dentures, and bridges.

Jewelry Design

The modelling of complex rings, necklaces and other jewellery requires an immense precision, which usually only a good resin 3D printer in the DLP process can offer. 3D printing models are mostly used in the lost wax process. A positive model is immersed in a refractory casting material to create a negative mold for final jewelry made of various metals.

Surgical precision

Buy the Zortrax Inkspire to create applications – from arts to technology – where precision makes all the difference. With a pixel size of 50x50 microns and a minimum layer thickness of 25 microns, 3D models can be 3D-printed without visible individual layers or vertical lines. The human eye cannot detect individual pixels because the image has more than 336 pixels per inch. The pixel density in 3D models (voxels) printed on your Zortrax Inkspire exceeds the value of detectability, regardless of the viewing angle.

Z-SUITE for Zortrax Inkspire

Z-SUITE is a special, functional and easy-to-use slicing and 3D printer software. It comes free with every Zortrax 3D printer. Now Z-SUITE has a number of additional features that make working with the Zortrax Inkspire an effortless experience.

Programmable Pause

The function of the programmable pause is very innovative and allows a simple workflow. First, Z-SUITE calculates how much resin is needed to produce each layer of the model. The software then uses this information to take a break to refill new resin. Then you can simply resume 3D printing.

Smart Support

The UV exposure times for your 3D models and support structure can be set independently.

Remote control

Simply pause and resume your 3D prints. You can monitor the progress of additive manufacturing on your Zortrax Inkspire at any time. This is made possible by connecting to the same Wifi network.

Buy the Zortrax Inkspire and you'll get a high-resolution DLP 3D printer with Wifi and Ethernet for scalable additive manufacturing.